Services

Modification & Conversation

Due to change in operating process parameter,fire or explosion hazards, updation of plants instrumentation, it is failure-proof to maintain optimum performance, while working under most adverse operating conditions often necesary to modify valve. NR Engineering has the design skills,material,staff and experience to confidently undertake work of modification and conversation like:

- Change of CV value.

- Change in flow characteristics.

- Conversion of on-off valve to control duty valve.

- Conversion of pressure balance trim and vice versa.

- Change of MOC of trim set from one metel to another.

- Change of valve action from air to open/close or vice versa.

- Conversion of manual valve to pneumatic/electrically operated valve.

Valve Testing

NR Engineering is fully equipped with all the modern valve testing facilities. Hydrostatic test is carried out on all valves to ensure that it meets the testing required against its primary pressure and temperature rating. In addition to this, seat leaking ang gland leakage testing is carried out to ensure satisfactory operations. when a test satisfactorily cpmpleted a test certificate is issued. AT the last stage after testing,as per client's request each valve is painted with modern hign anti resistance paint, with specific shade for speciic application.

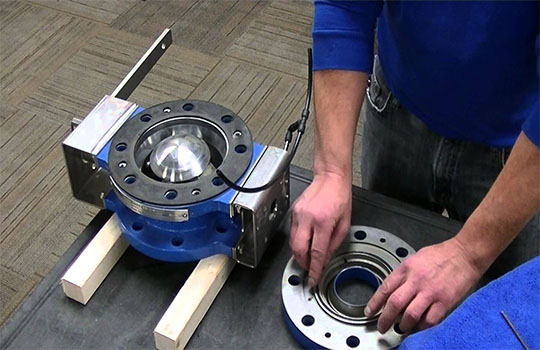

REPAIR AND RETROFIT

- Re-assembly of valve body, mounting of actuators,travel checking,actuator's bench set checking etc.

- Disassembly, inspection,evalution of complete valve,actuator.Cleaning of valve parts and its suitability for further use or its replacement or modification to upgrade the performance.

- Reconditioning of plug, seat, cage by depositing tough metel/stelliting hard facing.

- Machining on plug & seat contact, lapping and establishing perfect seat contact.

- Replacement of gland packing,gasket & seat rings

- Hydrostatic & seat leakage test and inspection of valves as per present standards

- Functional test on gland,joint and final calibration.

- Submission of test certication.

Part Replacement

- NR Engineering takes care of replacement and supply required spare parts for wide range of valves.

- NR Engineering is able to supply parts of equal quality to those provides by oroginal suppliers, often at comparatively lower cost and faster delivery.

- NR Engineering also supplies valve accessories like positioner I/P converter, Air filter pressure regulator, volume booster, limit switches, Air lock relay, Proximity switches, Hand wheel unit(TMH/SMH) stc.

Field Service

- NR Engineering also takes care of plant shut down jobs.

- NR Engineering has a team of experienced and qualified field engineers which are able to carry out work at the plant site as well as at our work shop.

- A portable mobile facility for overhauling, skin machining, testing, re-calibration and valve instrumentation activities to carry out the shut down within time frame available and can be provided where ever necessary.